ALCO Closed Loop > Breaker Breaker Closed Loop

|

Breaker Breaker is a low butyl, water soluble, biodegradable, non-flammable combination of solvents and detergents. Heavy duty cleaning often results in harm to the surface cleaned. Since Breaker Breaker is non-corrosive, it solves this problem by incorporating heavy duty cleaning agents and a solvent that is safe for most surfaces requiring this type of cleaning. This product has a wide range of cleaning applications, from floor scrubbing and industrial degreasing to kitchen cleaning.

Superior Grease & Soil Penetration & Retention Allow Breaker Breaker to be Used Economically. Use 1 Part with 5-10 Parts Water for Normal Deposits.

AVAILABLE IN: 4-1 Gal/Case Closed Loop

|

DIRECTIONS FOR USE:

Concrete, Hard Floors, Walls

Concrete, Hard Floors, Walls

- EXTRA HEAVY DEPOSITS: Use straight or dilute 50-50 with water.

- NORMAL DEPOSITS: Dilute 1 part with 5-10 parts water.

- Spray, brush, mop on surface – get it extra wet.

- Agitate with floor machine, stiff brush or wire brush.

- Keep surface wet during agitation period.

- Rinse with clean water, low or high pressure hose, hot or cold.

- Porous surfaces may require a second application or rinse.

- Engines, metal stock, airplanes, flues, machinery, aluminum, motors, conveyors, air conditioning ducts or grills, air filters, and refrigerators: Use straight or diluted.

- Spray, brush, mop on surface – get it extra wet.

- DEGREASING:

- Kitchen Grease: 1 part BREAKER-BREAKER to 7 parts water will remove heavy concentrations of grease from cupboards, walls and ceilings. Rinse and wipe dry. Wear rubber gloves for sensitive skin.

- Heavy kitchen grease areas such as ducts and grills: require a 1 part to 4 parts water dilution ratio.

- Kitchen Grease: 1 part BREAKER-BREAKER to 7 parts water will remove heavy concentrations of grease from cupboards, walls and ceilings. Rinse and wipe dry. Wear rubber gloves for sensitive skin.

|

Item #:

0179-CL |

Sizes:

4-1 Gal/Case Closed Loop |

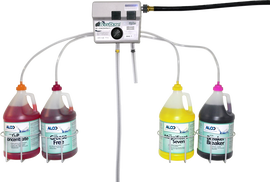

The Closed Loop System:

ALCO's Closed Loop Chemical Dispensing System is a problem solver. It ensures that you get the correct dilution every time so the job is done right without product waste. It’s also safer for you and your employees because it limits chemical handling.